The mixing tank is a cone type reverse discharge self-falling mixer, which can mix the main raw materials of quartz stone and other dry powder to ensure that the raw materials of the plate are uniform, so as to effectively control the color difference and improve production efficiency. The machine is composed of transmission mechanism, mixing mechanism, frame, blanking mechanism and electrical control system, etc., with novel structure and easy operation, it is suitable for all artificial stone and ceramic enterprises.

Weighing bucket is mainly used for quartz sand, quartz powder weighing, belt conveying and weighing, including weighing hopper.

The resin tank is mainly composed of tank body, lid, agitator, inlet and outlet, temperature control system, etc. The tank is made of corrosion-resistant material. It has the advantages of corrosion resistance, high temperature resistance, light weight and good sealing.

The color paste dispersion machine is mainly used to evenly disperse the color paste (a mixture containing pigments, fillers, etc.) into the quartz stone material to achieve the coloring and beautification effect of the material. Through efficient mixing and dispersion, it ensures that the color paste can fully penetrate into the tiny pores of the quartz stone material, so as to achieve the ideal coloring effect and material properties.

Particle mixer is mainly used for full uniform mixing of raw materials and resins, the use of double disk double motor planetary running structure, multi-axis multi-pulp scientific and reasonable cross mixing, mixing uniformity, high efficiency, no dead Angle.

The multi-color mixer is used to mix and stir 2 to 3 kinds of color materials after mixer, so that it becomes a multi-color material with uniform distribution of color, so that the plate pressing machine can press out a clear and diverse artificial stone plate. The equipment can combine the mixing action according to the wishes of the craftsman, and help the craftsman to deploy all kinds of high-quality color plates.

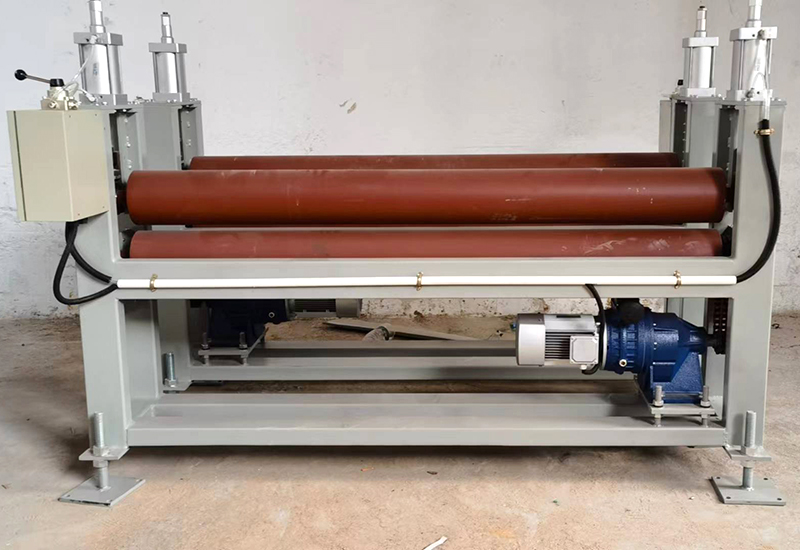

The material is crushed by two rollers rotating opposite each other. The roller skin is made of new wear-resistant material and has a long service life. The finished sand has uniform grain size, low needle flake content and no internal cracks.

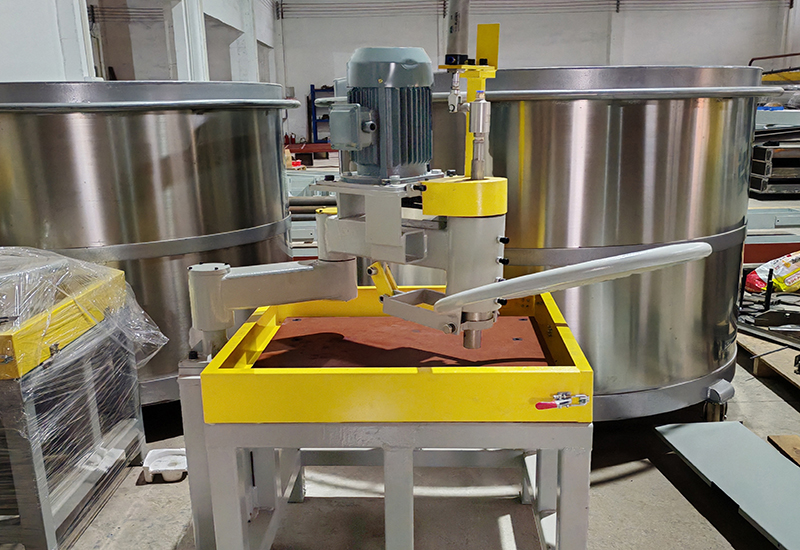

It has the functions of weighing, double pressing, dusting and dispersing, the cloth is uniform, smooth and efficient, and the whole machine can realize a variety of process actions. All materials in contact with the material are made of pollution-free materials, which can effectively eliminate pollution. Special design is adopted to ensure that the original mixed color will not be damaged, especially to avoid the phenomenon of running and uneven around the traditional drum cloth machine.

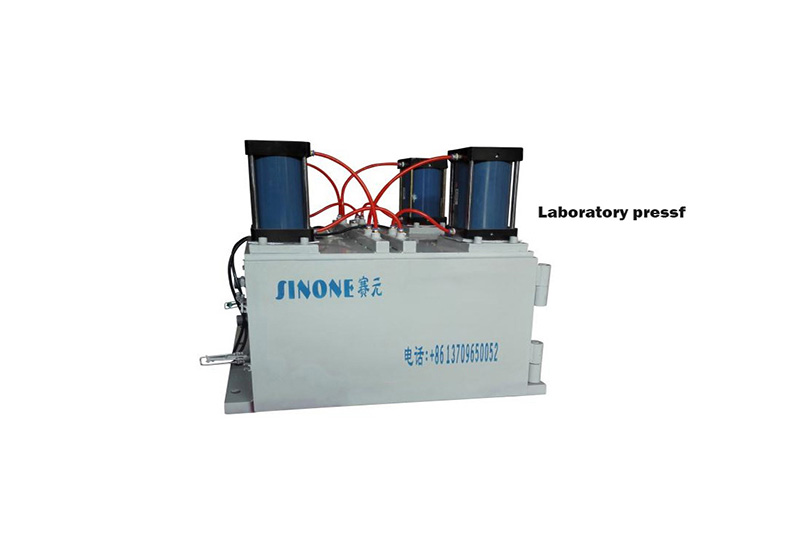

The press has double press function, equipped with powder sprinkling device, quartz stone pattern plate special equipment.

CNC pattern machine is composed of machine tool, conveyor belt, CNC system, servo system, spraying system, electrical system, lubrication system and dust removal system. High automation, stable operation, easy to operate. These features simulate the texture of natural stone. Such as: fish belly white and all kinds of line pattern plate.

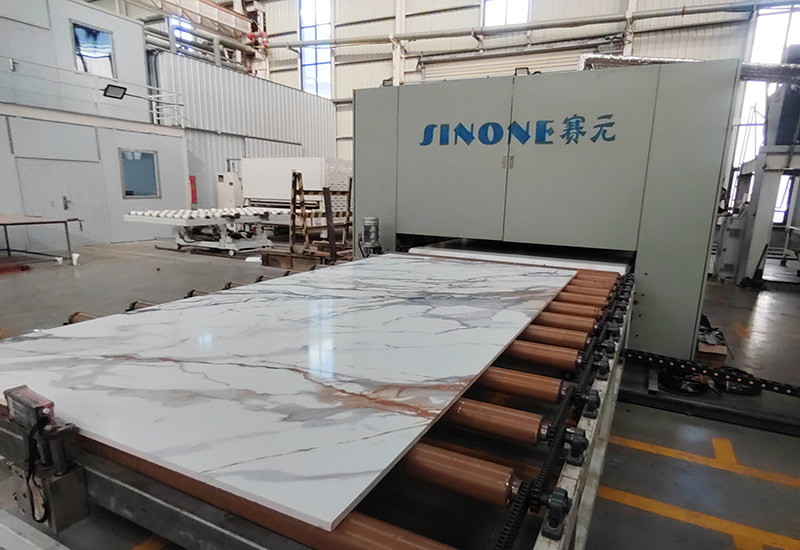

Seyuan Press is an efficient and energy-saving molding equipment, which can ensure the rapid molding of quartz SLATE in the environment of high vacuum and high-frequency vibration, and effectively ensure the flatness of the sheet, uniform texture, high density, high hardness and no porosity. The entire pressing process will be completed automatically: feed - vacuum - pressure - vibration - pressure relief - plate release.

Vertical splints curing furnace adopts steel plate 2 clip 1 hydraulic lifting, electric/natural gas heating heat transfer oil method, patented heat transfer plate processing technology, long direction with deep hole structure, the oil circuit in the heat transfer plate less turns, less heat transfer oil flow resistance, better heat transfer effect, more uniform heating temperature, lower energy consumption.

Adopts cylinder lifting and moving guide rail structure. Equipped with vacuum sucker, it can efficiently and stably complete material handling, assembly and other tasks.

Adopt electric chain lifting structure. The chain gear is lifted to the auxiliary, equipped with a safety net around it, and the plate is automatically transported to the vertical cooling box.

The vertical cooling box is specially used for cooling the quartz stone material after processing. It adopts the vertical structure design, the iron rod drum frame, the drum spacing is 300mm, which is easy to place and take out the quartz stone material. Two centrifugal fans are blown into the pressurized air circulation air cooling, rapid cooling to ensure its processing quality and performance; At the same time, cycloidal pin reducer is adopted, which has stable performance and low failure rate.

The upper (lower) plate adopts the integrated hydraulic system to drive the cylinder; Using manual drive roller transfer plate, electric walking function.

High degree of automation, equipped with electronic late abrasive detection system, the corresponding abrasive head can automatically alarm and remind the operator to replace the abrasive, high degree of intelligence, the use of large size touch screen, parameter adjustment more convenient.

The use of mechanical transmission, hydraulic drive or electrical control, the use of gear drive to drive the rotation of the turning platform, to achieve the smooth rotation of the plate, reduce the surface scratch of the plate, improve product quality, while reducing the labor intensity of the operator.

The newly designed automatic continuous grinding and polishing machine absorbs today's most advanced plate polishing technology and creates a number of patented technologies. Excellent material selection, reasonable structure, perfect processing technology, stable machine performance, high efficiency and energy saving. Electrical selection of international brand components, PLC control and through the LCD screen to achieve intelligent control. High swing speed beam device for smoother operation. Equipped with abrasive detection mechanism, automatic monitoring of abrasive consumption.

Using vertical and horizontal line cutting respectively, high working efficiency; Centring device, synchronous belt conveying, high diagonal cutting accuracy; PLC control system, with touch screen operation, easy to adjust cutting specifications.

En

En

Location:

Location: