The color paste disperser is primarily used to evenly disperse color paste (a mixture containing pigments, fillers, etc.) into quartz stone materials to achieve coloring and aesthetic effects. Through efficient stirring and dispersion, it ensures the color paste fully penetrates the micro-pores of the quartz stone material, thereby achieving ideal coloring results and material performance.

Our granular material mixer is primarily designed for the complete and homogeneous blending of raw materials and resin. Featuring a dual-disc, dual-motor planetary drive system, it employs a scientifically optimized multi-shaft, multi-blade counter-rotating mixing configuration. This ensures consistent and efficient mixing with zero dead zones.

The multi-color mixer is designed to combine 2 to 3 pre-mixed color batches from the primary mixer. This ensures the creation of a multi-toned material with a uniform distribution of hues, which in turn allows the pressing machine to produce artificial stone slabs featuring distinct and varied patterns. The system offers customizable blending sequences, empowering technicians to develop a wide range of high-quality decorative slabs.

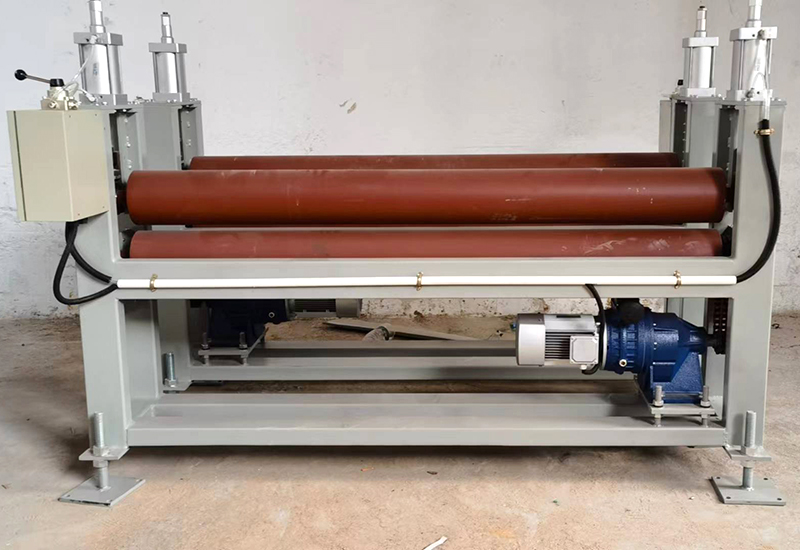

Our dual roller crushing mill employs two opposingly rotating rollers to effectively crush materials. The roller surfaces are constructed from an advanced wear-resistant material, providing extended operational lifespan. The processed aggregate exhibits consistent particle size distribution, minimal presence of elongated or flaky particles, and is free from internal fissures.

This automatic material distributor features weighing, dual pressing, powder scattering, and material loosening functions. It ensures uniform, level, and efficient material distribution, and the entire machine can perform various process actions. All materials in contact with the raw materials are non-polluting, effectively preventing contamination. Its special design guarantees that the original mixed colors are not damaged, especially avoiding the material spillage and uneven distribution around the edges seen in traditional drum-type distributors.

Our press is engineered with a dual-stage pressing mechanism and an integrated powder dispensing unit. This specialized equipment is specifically designed for the production of patterned quartz stone slabs.

Our CNC veining machine comprises a precision machine tool, a conveyor system, a numerical control unit, servo drives, a spraying apparatus, an electrical control system, a lubrication system, and a dust extraction system. It offers a high degree of automation, stable performance, and user-friendly operation. These advanced features enable the simulation of natural stone veining, including patterns like Calacatta White and various linear designs on slabs.

En

En

Location:

Location: