The Mixing Tank is a cone-shaped, reverse-discharge, gravity-type mixer designed for blending quartz stone raw materials and other dry powders. It ensures uniform particle distribution in the slab mixture, effectively minimizing color variation and enhancing production efficiency.

The machine consists of a drive mechanism, mixing unit, frame, discharge system, and electrical control system. Featuring a novel structure and user-friendly operation, it is well-suited for all artificial stone and ceramics manufacturers.

The Weighing Hopper is primarily used for weighing quartz sand and quartz powder. It includes a belt conveyor system and a small hopper for material weighing.Weighing Hopper

Resin Tank is primarily composed of the tank body, lid, agitator, inlet and outlet ports, and a temperature control system. The tank is made from corrosion-resistant materials, offering excellent durability against high temperatures.

Key features include corrosion resistance, high-temperature tolerance, lightweight design, and superior sealing performance.

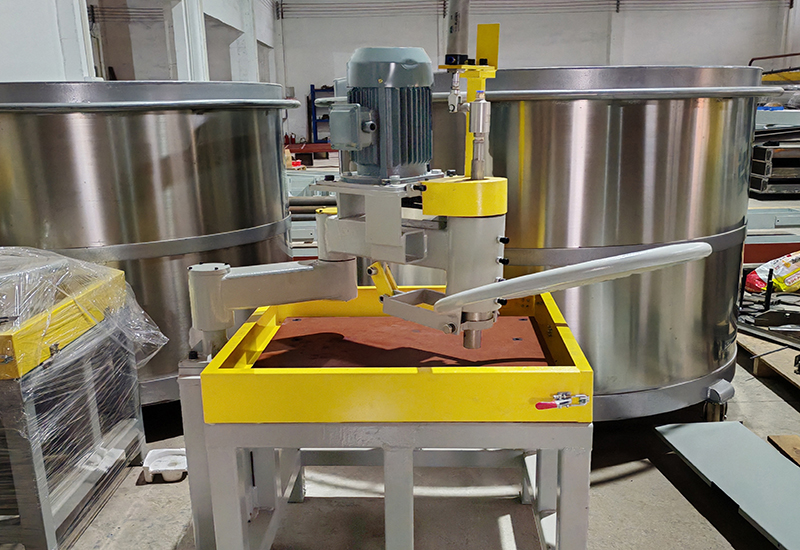

The color paste disperser is primarily used to evenly disperse color paste (a mixture containing pigments, fillers, etc.) into quartz stone materials to achieve coloring and aesthetic effects. Through efficient stirring and dispersion, it ensures the color paste fully penetrates the micro-pores of the quartz stone material, thereby achieving ideal coloring results and material performance.

Our granular material mixer is primarily designed for the complete and homogeneous blending of raw materials and resin. Featuring a dual-disc, dual-motor planetary drive system, it employs a scientifically optimized multi-shaft, multi-blade counter-rotating mixing configuration. This ensures consistent and efficient mixing with zero dead zones.

The multi-color mixer is designed to combine 2 to 3 pre-mixed color batches from the primary mixer. This ensures the creation of a multi-toned material with a uniform distribution of hues, which in turn allows the pressing machine to produce artificial stone slabs featuring distinct and varied patterns. The system offers customizable blending sequences, empowering technicians to develop a wide range of high-quality decorative slabs.

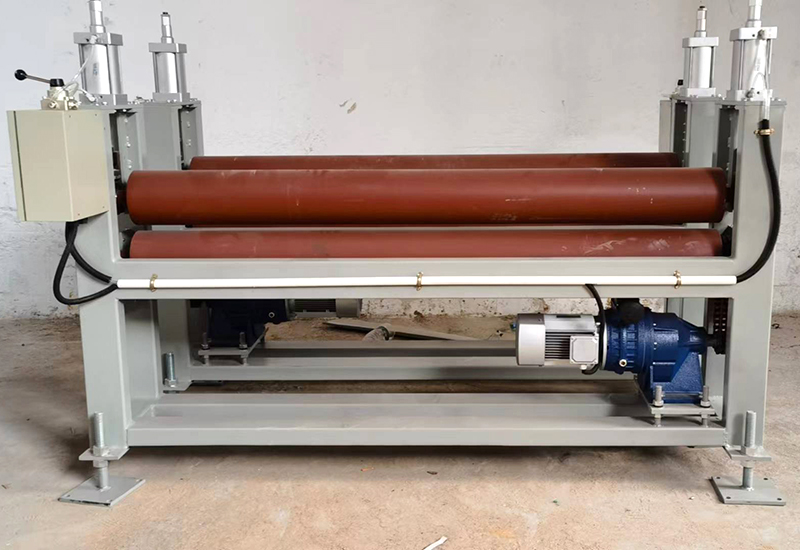

Our dual roller crushing mill employs two opposingly rotating rollers to effectively crush materials. The roller surfaces are constructed from an advanced wear-resistant material, providing extended operational lifespan. The processed aggregate exhibits consistent particle size distribution, minimal presence of elongated or flaky particles, and is free from internal fissures.

This automatic material distributor features weighing, dual pressing, powder scattering, and material loosening functions. It ensures uniform, level, and efficient material distribution, and the entire machine can perform various process actions. All materials in contact with the raw materials are non-polluting, effectively preventing contamination. Its special design guarantees that the original mixed colors are not damaged, especially avoiding the material spillage and uneven distribution around the edges seen in traditional drum-type distributors.

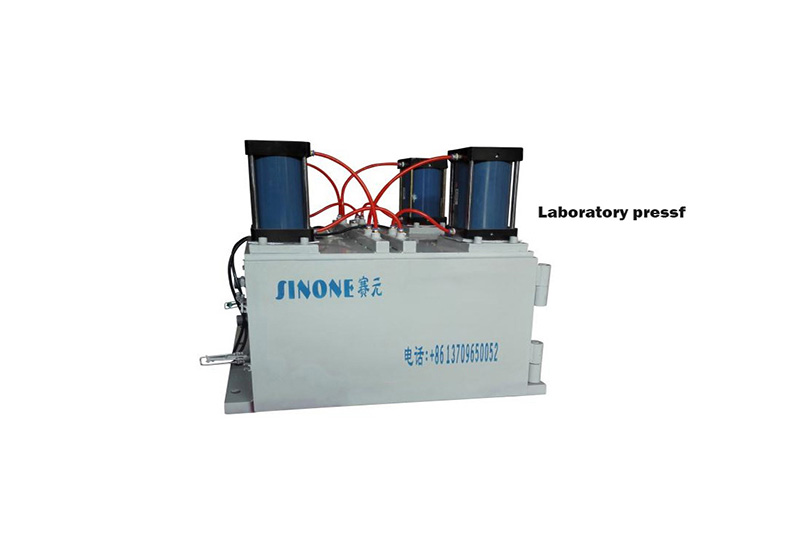

Our press is engineered with a dual-stage pressing mechanism and an integrated powder dispensing unit. This specialized equipment is specifically designed for the production of patterned quartz stone slabs.

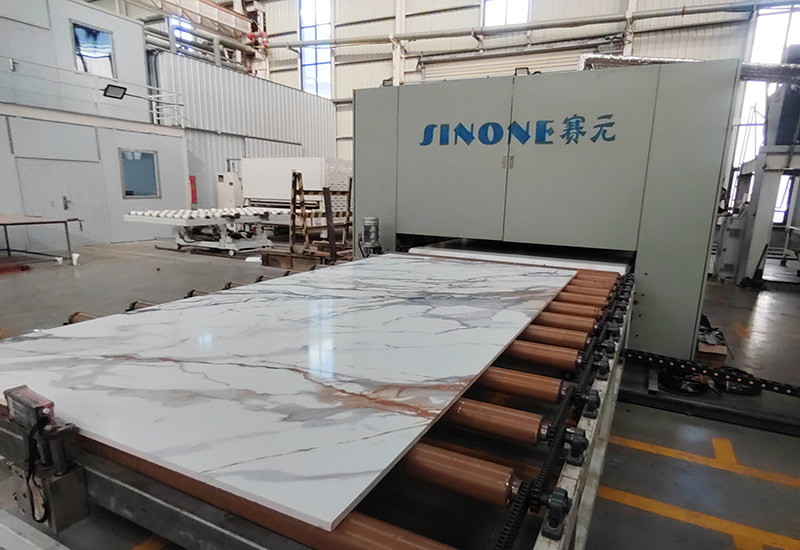

Our CNC veining machine comprises a precision machine tool, a conveyor system, a numerical control unit, servo drives, a spraying apparatus, an electrical control system, a lubrication system, and a dust extraction system. It offers a high degree of automation, stable performance, and user-friendly operation. These advanced features enable the simulation of natural stone veining, including patterns like Calacatta White and various linear designs on slabs.

The Sinone press is a high-performance and energy-efficient molding machine engineered to ensure the rapid formation of quartz stone slabs under conditions of high vacuum and high-frequency vibration. This effectively guarantees exceptional slab flatness, consistent texture, high density, superior hardness, and zero porosity.

The entire pressing cycle is fully automated: material feeding - vacuum application - pressurization - vibration - pressure release - slab discharge.

Our vertical slab curing oven utilizes a 2-steel-plate, 1-hydraulic-lift clamping mechanism and employs electric/natural gas heating of thermal oil. It incorporates a patented thermal conductive plate processing technique featuring a longitudinal deep-hole structure.

The internal oil pathways within the conductive plates are designed with minimal turns, significantly reducing thermal oil flow resistance, enhancing heat transfer efficiency, ensuring more uniform heating temperatures, and minimizing energy consumption.

Our automated vacuum suction lifter features a cylinder-driven lifting mechanism and linear guide rails for movement.

Equipped with high-performance vacuum suction cups, it ensures efficient and stable material handling, assembly operations, and more.

Our lifter utilizes an electric chain-driven elevation system.

It incorporates chain and sprocket-assisted lifting, includes a comprehensive four-sided safety net, and automatically transports the slabs to the vertical cooling unit.

The vertical cooling box is specialized equipment for cooling processed quartz stone materials. It features a vertical structural design, an iron bar roller frame with a roller spacing of 300mm for easy placement and removal of quartz stone materials.

Rapid cooling is achieved through a pressurized circulating airflow generated by dual centrifugal fans, ensuring optimal processing quality and material performance. Furthermore, it utilizes a cycloidal pin gear reducer, known for its stable operation and minimal downtime.

Our automated slab turnover machine utilizes an integrated hydraulic system with cylinder actuation for (upper/lower) slab loading.

Slab transfer is facilitated by manually operated rollers, and the unit is equipped with an electric traversing function.

Our rotary thickness calibrator offers a high level of automation and incorporates an intelligent electronic abrasive wear detection system.

Upon depletion of abrasive material on a specific grinding head, the system automatically triggers an alarm and prompts operator replacement. Its advanced intelligence is further enhanced by a large touchscreen interface, providing streamlined parameter adjustment.

Our 180° slab turnover machine employs mechanical, hydraulic, or electrical actuation to rotate the tilting platform through a gear transmission mechanism. This ensures smooth and controlled flipping of slabs, minimizing surface damage, enhancing product quality, and significantly reducing the physical demands on operators.

Our newly engineered, fully automated continuous grinding and polishing machine integrates the most advanced slab polishing technologies and incorporates numerous patented innovations. Featuring premium material selection, an optimized structure, and refined manufacturing processes, this machine delivers stable, high-efficiency, and energy-saving performance.

It predominantly utilizes internationally renowned electrical components and employs PLC control accessible via an LCD touchscreen for intelligent operation. The high-oscillation speed beam assembly ensures enhanced operational stability. Furthermore, it is equipped with an abrasive monitoring system for the automatic tracking of abrasive consumption.

Our bridge cutting machine employs in-line longitudinal and transverse cutting for high operational efficiency. Equipped with a centering mechanism and synchronous belt conveyance, it ensures precise diagonal cutting accuracy. It adopts a PLC control system with a touchscreen interface, adjusting cutting dimensions is convenient and straightforward.

En

En

Location:

Location: